What is The Composition of Brass

Brass is a popular material in many industries. It’s strong, durable, and looks great & also used idely used throughout history due to its exceptional properties and versatility. In this guide, we’ll explore the different types of brass and their compositions in this article and help you choose the right one for your needs.

Understanding Brass: An Overview

Brass is a metallic alloy composed primarily of copper (Cu) and zinc (Zn). It is commonly categorized as a substitutional alloy since the atoms of copper and zinc replace each other in the crystal lattice structure. The proportion of these two elements in brass can vary, resulting in different types and grades of brass with distinct characteristics.

The Main Components of Brass

-

- Copper (Cu): Copper is the primary component of brass, providing its inherent strength, durability, and excellent thermal and electrical conductivity. The percentage of copper in brass typically ranges from 55% to 90%, depending on the desired properties and applications of the alloy.

- Zinc (Zn): Zinc is another essential element in brass. It enhances the alloy’s hardness, corrosion resistance, and machinability. The percentage of zinc in brass usually ranges from 10% to 45%.

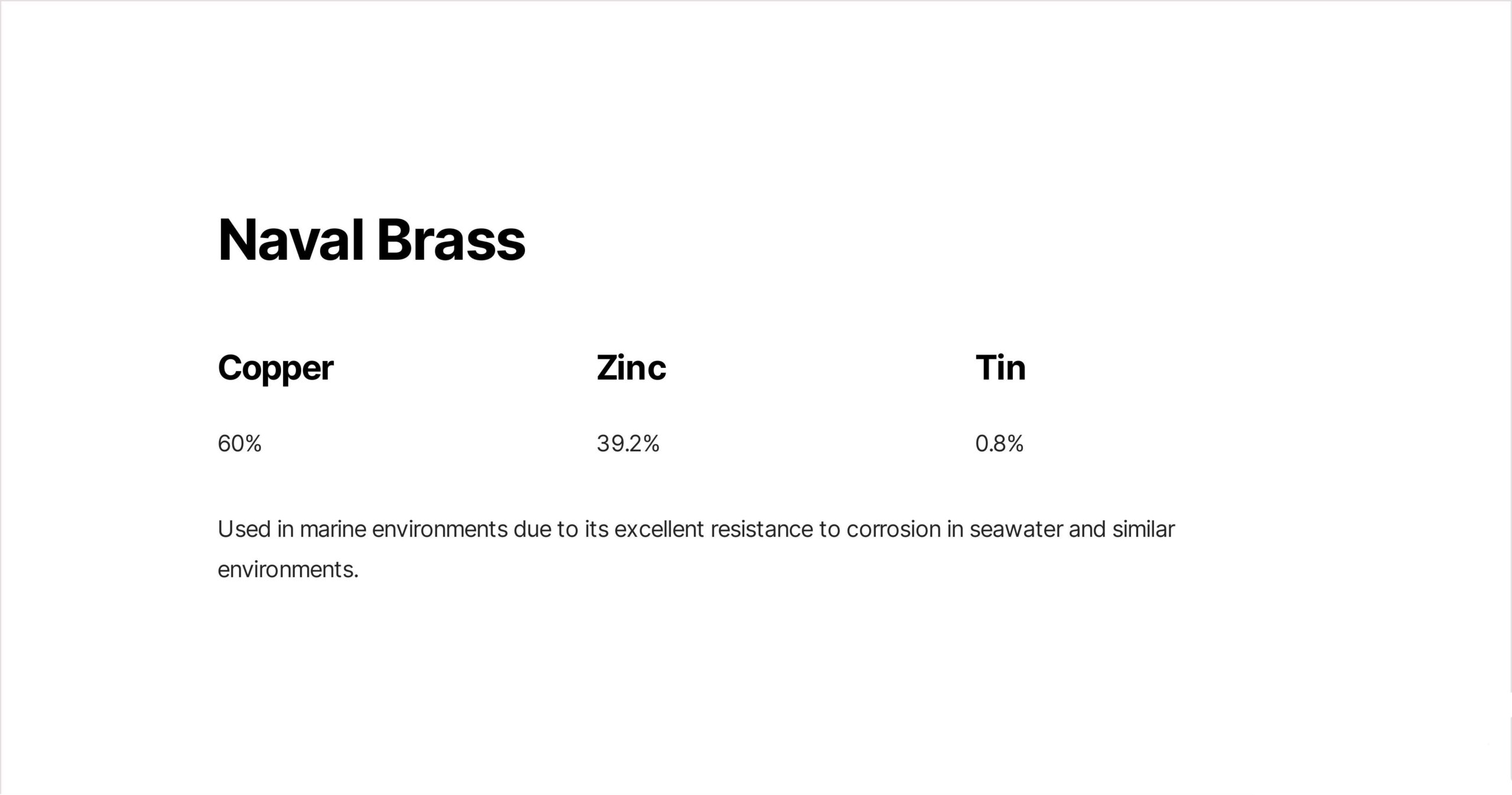

- Other Alloying Elements: Besides copper and zinc, brass can also contain small amounts of other elements to further modify its properties. Some common alloying elements include lead, tin, aluminum, nickel, and manganese. These elements are added in trace amounts to improve specific characteristics such as strength, color, or resistance to certain environmental conditions.

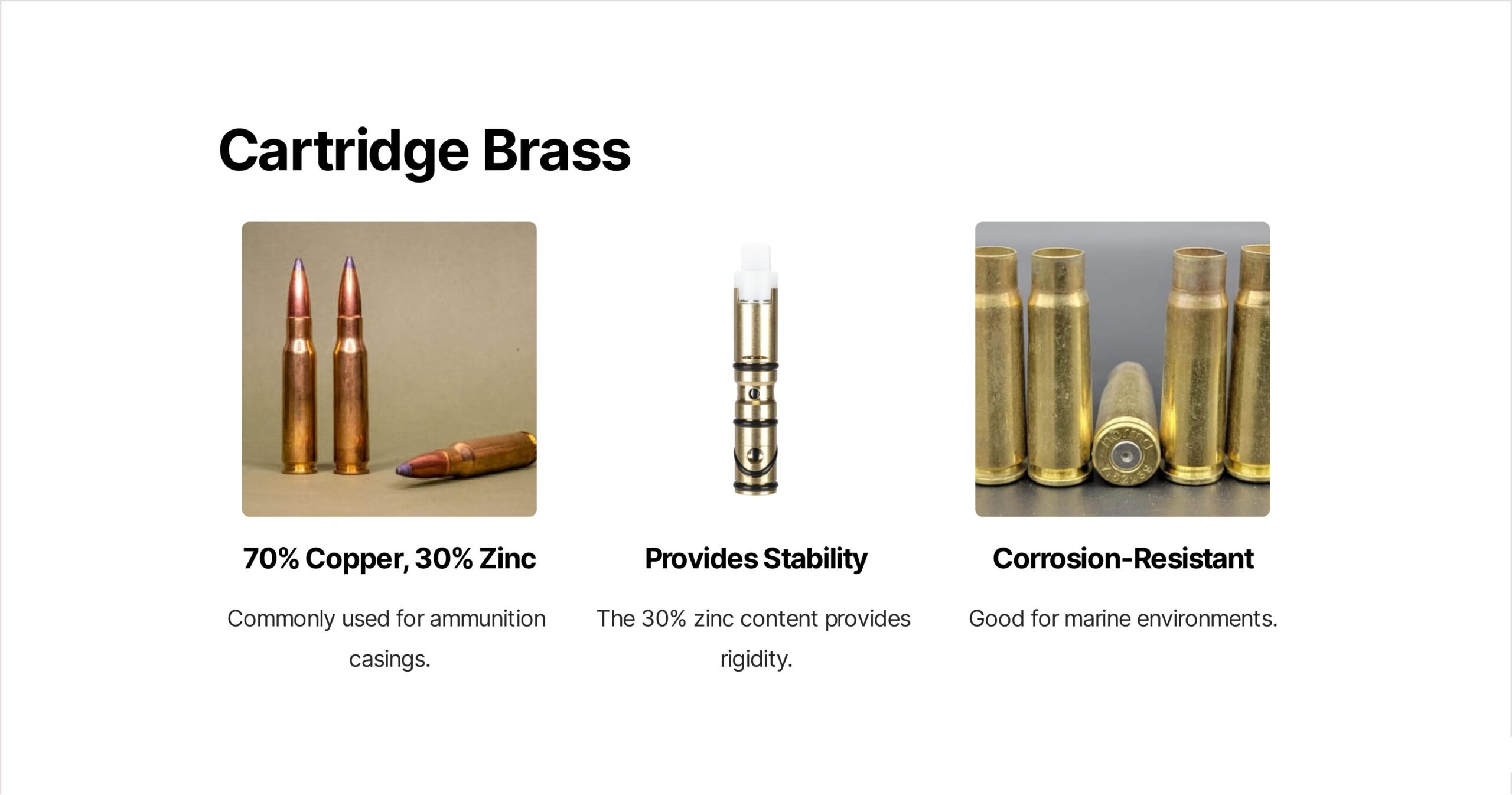

Types of Brass and Their Compositions

Brass alloys can vary significantly in composition, leading to different types and grades suitable for diverse applications. Here are some commonly used brass types:

-

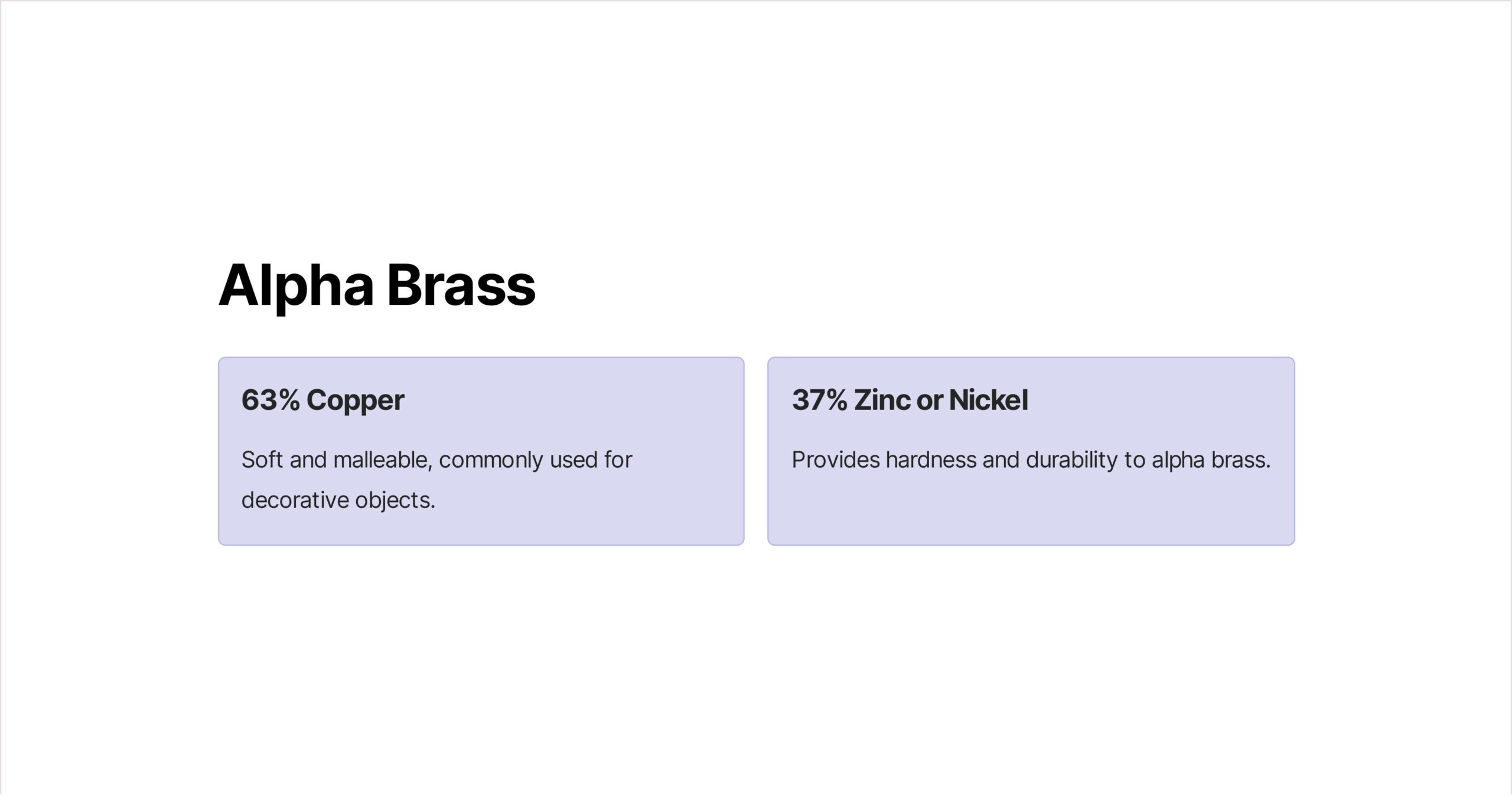

- Alpha Brass: Alpha brass contains a higher percentage of copper (65% to 90%) and lower levels of zinc. This type of brass exhibits excellent corrosion resistance, malleability, and acoustic properties. It is often used in musical instruments, decorative items, and electrical connectors.

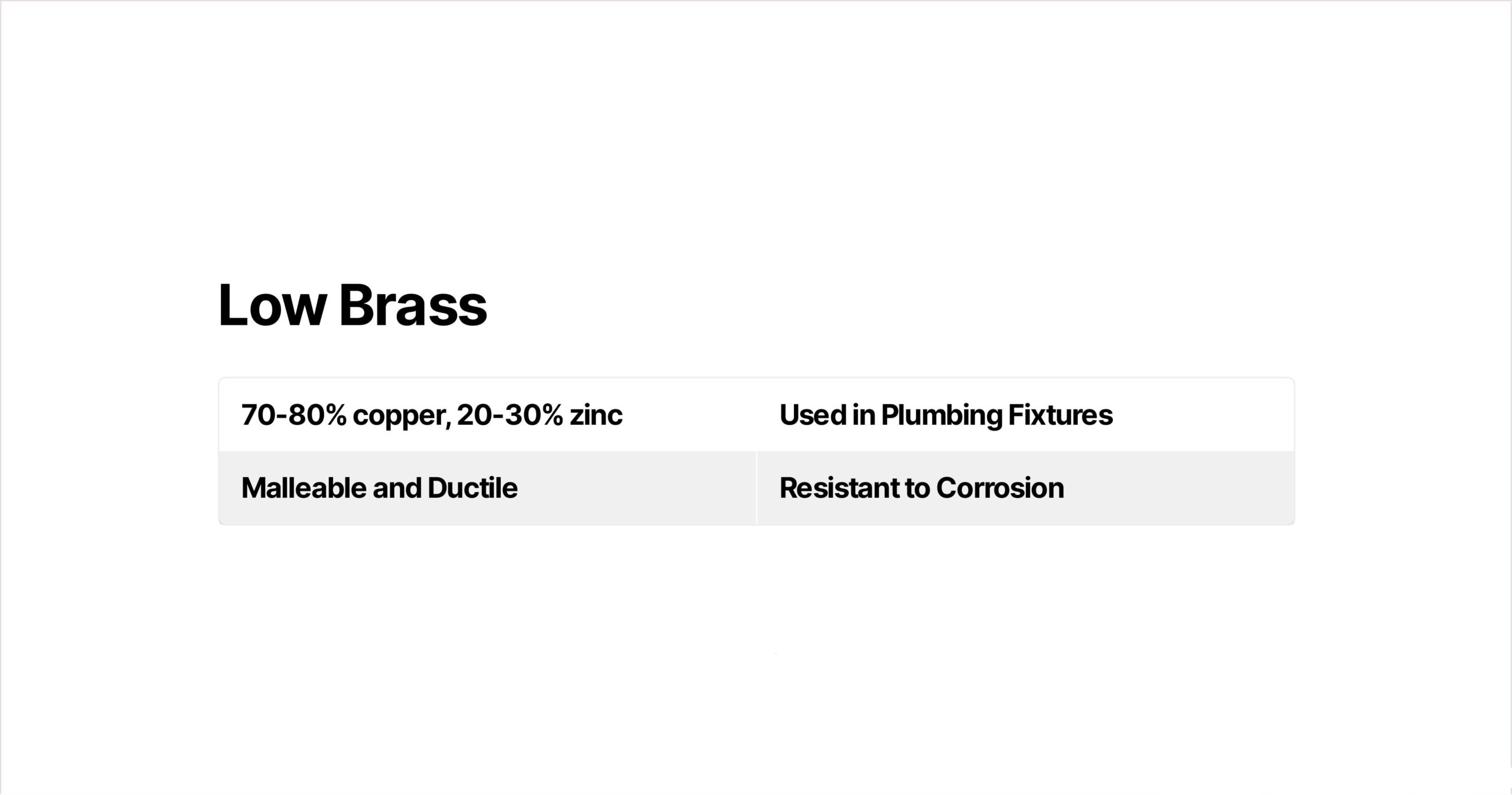

- Alpha-Beta Brass: Alpha-beta brass, also known as duplex brass, has a balanced composition of copper (55% to 65%) and zinc. This type of brass combines the desirable properties of both alpha and beta phases, making it suitable for applications that require both strength and formability. It finds applications in plumbing fittings, automotive components, and marine hardware.

- Beta Brass: Beta brass contains a higher percentage of zinc (45% to 55%) and exhibits increased strength, hardness, and wear resistance. This type of brass is commonly used in applications where high strength and machinability are essential, such as valves, gears, and locks.

The Advantages of Using Brass

Brass offers numerous advantages that make it a preferred material in various industries:

-

- Corrosion Resistance: Brass demonstrates excellent resistance to corrosion, making it ideal for applications in humid or corrosive environments.

- High Thermal and Electrical Conductivity: Brass possesses exceptional thermal and electrical conductivity, allowing it to efficiently dissipate heat and conduct electricity.

- Malleability and Formability: Brass can be easily shaped, bent, and formed into intricate designs, making it suitable for artistic and decorative applications.

- Aesthetic Appeal: Brass exhibits an attractive golden appearance, adding an element of elegance and sophistication to products and structures.

- Durability: Brass is a highly durable material, capable of withstanding harsh conditions and resisting wear and tear over time. It ensures longevity and reliability in various applications.

- Low Friction: Brass has a low coefficient of friction, making it an excellent choice for components that require smooth movement or sliding, such as bearings and valves.

- Recyclability: Brass is a sustainable choice as it is fully recyclable without losing its inherent properties. This promotes environmental consciousness and reduces the demand for new raw materials.

Applications of Brass

Due to its unique combination of properties, brass finds extensive usage across diverse industries:

-

- Construction and Architecture: Brass is widely employed in architectural hardware, fittings, and decorative elements, adding a touch of elegance to buildings and structures.

- Electrical and Electronics: Brass is a preferred material for electrical connectors, terminals, and components due to its excellent electrical conductivity and corrosion resistance.

- Automotive: Brass is used in various automotive applications, including radiator cores, pistons, connectors, and electrical terminals, thanks to its heat transfer capabilities, durability, and electrical conductivity.

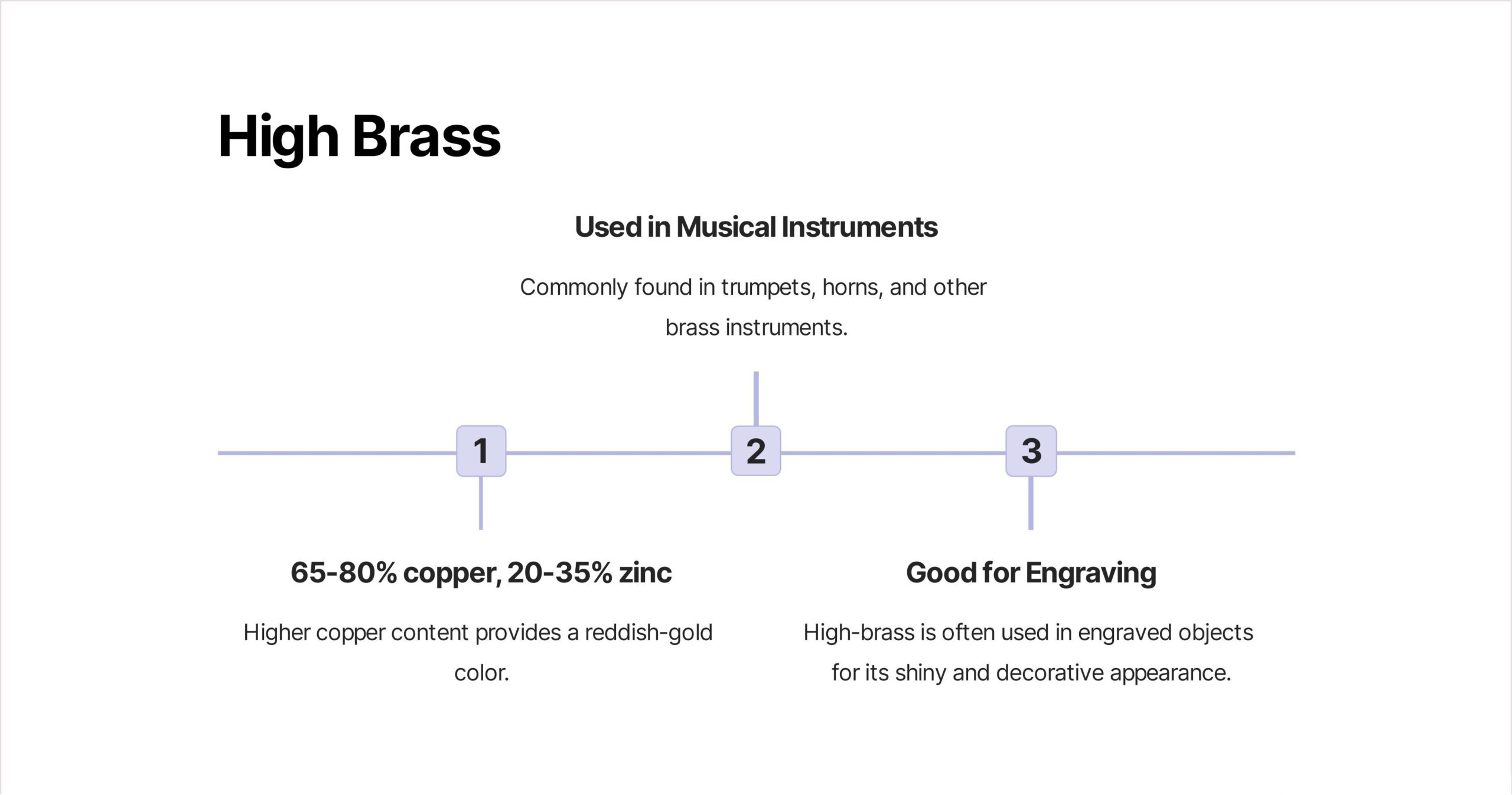

- Musical Instruments:Brass instruments such as trumpets, trombones, and saxophones are made primarily from brass due to its acoustic properties, malleability, and aesthetic appeal.

- Plumbing and Sanitary Fittings: Brass fittings and valves are widely used in plumbing systems due to their corrosion resistance, durability, and ease of installation.

- Jewelry and Decorative Items: Brass jewelry and decorative items have gained popularity for their unique aesthetic appeal, affordability, and versatility in design.

- Marine Applications: Brass’s resistance to corrosion in seawater makes it suitable for marine hardware, ship fittings, and underwater equipment.

In Conclusion

Brass, a versatile alloy composed of copper and zinc, offers a wide range of advantages across various industries. Its unique combination of properties, including corrosion resistance, high thermal and electrical conductivity, malleability, and durability, makes it a preferred choice for numerous applications. From construction to electronics, automotive to musical instruments, and plumbing to decorative items, brass continues to demonstrate its value and versatility. By understanding the composition of brass and its remarkable attributes, industries can harness its potential to create innovative and reliable products for a multitude of purposes.

Remember, when it comes to reliability, functionality, and aesthetic appeal, brass shines as a timeless choice in the world of materials.

I have been surfing online more than 4 hours today, yet I

never found any interesting article like yours. It is pretty worth enough for me.

In my opinion, if all web owners and bloggers made good content as you did,

the web will be much more useful than ever before.