- Brass Components

- Brass Pneumatic Fittings

- Brass Forging Components

- Brass Anchors

- Brass Pool Anchors

- Brass Electrical Fittings

- Brass Cable Glands

- Brass Switch Gear Parts

- Brass Sanitary Parts

- Brass Gas Fittings

- Brass Ceramic Cartridge Fittings

- Brass Casting Components

- Brass Billets

- Brass Auto Parts

- Brass Block Meter Parts

- Brass Washers

- Brass Barb Hose Fittings

- Brass Inserts

- Brass Fasteners

- Screws Fasteners

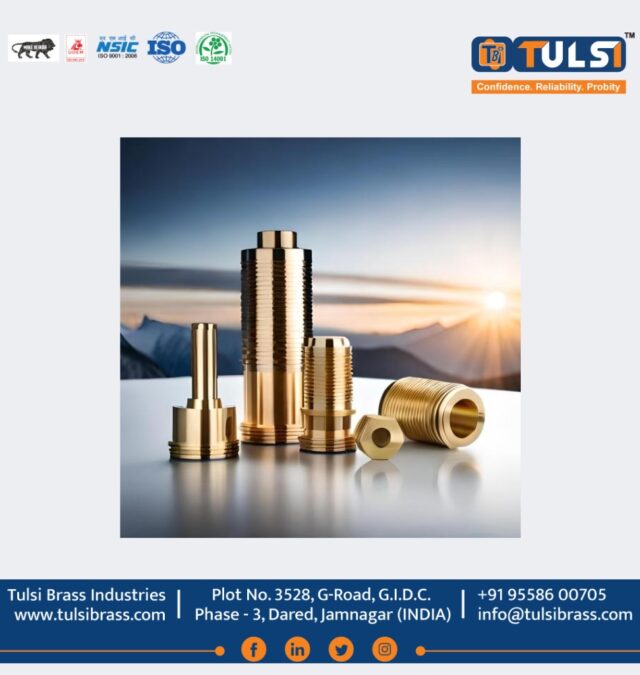

Brass Components

Tulsi Brass Industries excels as a leading manufacturer and exporter of high-quality brass components, renowned for their precision and durability. Firstly, our unwavering commitment to excellence is reflected in our utilization of advanced machining techniques and cutting-edge infrastructure, ensuring the consistent production of precision brass components that meet the highest industry standards. Moreover, this guarantees a flawless fit for your applications, as our extrusion components are meticulously crafted to exacting dimensions

Secondly, as a customer-centric organization, we highly value the importance of timely delivery in providing exceptional service. Therefore, our dedicated logistics team works tirelessly to ensure the prompt and efficient delivery of brass turned components to customers worldwide, spanning Australia, the USA, the UK, the Middle East, Europe, and beyond.

Furthermore, our efficient logistics and supply chain management systems, combined with clear communication and an unwavering commitment to delivering quality brass components & parts, empower us to consistently meet our customers’ deadlines. Consequently, this level of dedication not only ensures customer satisfaction but also fosters long-lasting relationships built on trust and reliability.

In conclusion, please feel free to reach out to me if you have any further questions or require additional information for Brass Precision Components.

At Tulsi Brass Industries, we are a state-of-the-art turning plant specializing in the manufacturing of precision-turned and milled parts for clients spanning various industries. We take immense pride in our ability to offer an extensive range of high-quality brass components, crafted with utmost precision and finesse.

Even a small imperfection in the brass components can lead to failure of the system, huge breakdown or hazards and to resolve this ambiguity of the thousands of industries, Tulsi Brass Industries introduces a nonpareil assortment of brass precision turned parts, manufactured using the CNC machining technology and following the international quality controlled manufacturing methodologies.

Our brass precision turned parts attributes precise design, dimensional precision, high tolerance, better surface finish and a truly seamless construction that guarantees for the unfailing operations everlastingly.

When it comes to brass turned components or parts, we prioritize meticulous craftsmanship and utilise only the finest-grade materials. our unwavering commitment to quality guarantees exceptional strength, durability, and corrosion resistance, thereby making our extrusion brass components the optimal choice for a diverse range of applications.

- ISO metric (MM Threads)

- BA Threads

- BSW Threads

- UNC & UNF Threads

- As per our Customers Requirements

- Free Cutting Brass as per BS 249 Type (I)

- Stainless Steel

- 6061-t6 Aluminum Alloys / 6063 Aluminum Alloys

- Mild Steel

- Silicon Bronze

- Copper Alloys Naval Brass C46400

- Different Alloys in Copper, Brass, Mild Steel, Iron etc

- Any Special Material Composition as per customers requirement for Precision Parts

That is to say, screws that are nickel plated undergo an initial copper plating process, after which a layer of nickel is electrolytically applied to the copper finish. This nickel plating is commonly used in fasteners for electrical appliances and areas that experience condensation. in fact, It is worth noting that approximately 80% of the nickel consumed in plating is for decorative applications.

In other words, nickel plating provides screws with excellent appearance and offers good performance in preventing corrosion. However, it is important to clarify that nickel plating may exhibit poor performance in salt spray tests, which are conducted to evaluate the resistance of a material to corrosion under harsh conditions.

Table 1 Lists the Following Minimum Thicknesses:

-

Grade A – 0.0016 Min Thickness Plating

-

Grade B – 0.0012 Min Thickness Plating

-

Grade C – 0.0010 Min Thickness Plating

-

Grade D – 0.0008 Min Thickness Plating

-

Grade E – 0.0006 Min Thickness Plating

-

Grade F – 0.0004 Min Thickness Plating

-

Grade G – 0.0002 Min Thickness Plating

- Black oxide brass finish

- Clear brass finish

- Gold brass finish

- Nickel brass finish

- Antique brass finish

- Silver brass finish

- Brushed brass finish

- Polished brass finish

- Textured brass finish

- Black oxide finish for components

- Gold finish for components

- Silver finish for components

- Brushed finish for components

- Polished finish for parts

- Satin brass finish

- Clear finish for parts

- Nickel finish for parts

- Protective wall panels

- Antique finish for parts

- Satin finish for components

- Textured finish for parts

Brass Components or Brass Parts Dimension(l*w*h): Starging From 4mm Dia To 100mm Dia And Till 200 mm Length Millimeter (Mm).

- CNC Milling Machines

- CNC Lathe Machines

- Automatic Milling

- Conventional Milling

- Conventional Lathe

- Grinding Machine

- Brass Sloting Machine

- Threading Machine

- Band Saw

- Drilling Machine

- Vertical Machining Ceneter

- Profile Projector

- Height Masters

- Roundness Tester

- Hardness Tester

- Various Types of Thread Gauges, Depth Gauge, Wire Gauges and Ring Gauges

- Microscopes

- Digital Vernier Caliper

Likewise, our core markets extend to various regions around the world. similarly, we serve customers in Canada, United States (East Coast, West Coast, Midwest), Singapore, Thailand, Saudi Arabia, UK, Italy, Qatar, Russia, Spain, Poland, Portugal, Israel, Germany, Sweden, Dubai, and France. In the same vein, we strive to meet the diverse needs of our global clientele, ensuring that our high-quality brass components are accessible and readily available across these international markets.

- CNC Sliding Head Multi Spindle Machine – 2

- VMC Machines – 1

- S.P.M. Machines – 2

- Cam Operated Trobe Turning Machine – 50

- Automatic Drilling Machines – 5

- Automatic Cutting Machines – 1

- Automatic Slotting Machines – 2

- Automatic Threading Machines – 5

- Shaping Machines – 1

- Header Machines – 6

- Power Press Machines – 1

- Debarring Machines – 1

- Spot Welding Machines – 1

- Marking Machine – 2

- Automatic Packaging Machine – 2

- Heat Treatment Machine – 1

- Electric Melting Furnace – 1

- Extrusion Press – 1

Firstly, Brass is a metal alloy that is typically made with a combination of copper & zinc. However, it is important to note that other metals like aluminum, lead, and arsenic may be added as alloying agents to improve properties like machinability and corrosion resistance. On the other hand, brass can be made harder or softer by varying the amount of copper and zinc used.

That is to say, when it comes to brass and Cooper Alloy rods, there are different grades available to cater to various applications. In other words, these grades of brass and cooper alloy rods are specifically designed and manufactured to meet the specific requirements and demands of different industries and sectors.

Without a doubt, This variety of grades allows us to provide customized solutions and clarify that we can offer the right type of brass and Cooper Alloy rods for specific projects and applications.

But, not all brass rods are the same. Free Cutting Brass Rods, for example, are available in grades such as B 16 C 38500, BS 2874 CZ – 121Pb3 or CZ124, C 36000, IS319 Grade I/ II/ III, and JIS3250 H C3604 or C3602.

However, if you require forging applications, Forging Brass Rods are more suitable. They consist of ASTM B 124 C37700, BS 2874 CZ 122, and IS 3488 Forging Brass. Additionally, for riveting purposes, you can opt for Riveting Brass Rods, which include IS 4170 CuZn40, BS 2874 CZ109, JIS 3250 H C2800, ASTM B171 C 36500, IS 4413 CuZn37, and BS 2872 CZ108.

On the other hand, if you are looking for brass rods with excellent corrosion resistance, Naval Brass Rods are the ideal choice. They encompass IS291 Grade I or II, BS 2874 CZ 112, JIS 3250 C4622, and ASTM C48200.

When it comes to electrical applications, Electrolytic-Tough-Pitch (ETP) Copper is widely used. It boasts a minimum conductivity rating of 100% IACS and a purity of 99.9%. However, it is worth noting that it typically has an oxygen content of 0.02% to 0.04%.

On the other hand, Deoxidized High Phosphorus (DHP) copper offers unique properties. It is commercially pure copper that has been deoxidized with phosphorus. As a result, it retains a relatively high residual phosphorus content. Copper alloy 122, for example, is not susceptible to hydrogen embrittlement. However, it does have relatively low electrical conductivity due to the phosphorus content.

Meanwhile, we provide a customized labeling & packaging for Brass Components or Parts. Additionally, we offer different packing options with a standard size wooden pallet for handling and storage efficiency.

Firstly, we package our Brass Components in either a carton or a wooden box, depending on the size of the parts. However, it should be noted that in the specific case of (Do-It-Yourself) retail packages, customers may have very specific packaging requirements. For example, they may prefer the use of plastic bags, cartons, or plastic boxes. Moreover, regardless of the packaging method, we ensure that the outer package includes the brand name and type number. Furthermore, retail customers often request specific labels, including a Barcode Sticker.

Furthermore, during ocean transportation, we take utmost care in preparing the package. Specifically, we meticulously select a suitable wooden, steel, or plastic pallet and ensure it is securely wrapped with a plastic sheet and sealed with metal strips. Most importantly, we consider customer requirements and preferences to determine the appropriate size of the boxes, taking into account the weight per box and handling possibilities.

Moreover, for the purpose of easy identification during transport, we place great importance on labeling the packaging. In fact, it is crucial to include the following information on the labels: quantity, weight, the specific components or parts being shipped, and the name of the producer. Additionally, we ensure that the labels are prominently displayed and easily visible.

In conclusion, our focus on customized labeling, diverse packing options, and meticulous attention to detail in packaging and labeling ensure that our Brass Components or Parts reach our customers in optimal condition, with all necessary information readily available for efficient handling and identification during transportation.

Therefore, we dispatch our brass components or parts from various ports including ICD Khodiyar-Ahmedabad, Mundra port, Nahava Sheva Port-Mumbai, Air Cargo Complex-Ahmedabad, and BOM Air Cargo Complex-Mumbai, among others. Our priority is to ensure efficient and reliable transportation to meet the needs of our customers.

Payment: 30% advance and rest of against T/T At sight against copy of B/L.